taug qab cov menyuam PC75 Undercarriage Cheebtsam

Peb cov khoom tau lees paub dav thiab ntseeg tau los ntawm cov neeg siv khoom thiab tuaj yeem ua tau raws li kev xav tau ntawm kev lag luam thiab kev sib raug zoo rau kev taug qab cov menyuam PC75 Undercarriage Components, Yog xav paub ntxiv lossis koj yuav tsum muaj lus nug txog peb cov kev daws teeb meem, feem ntau koj yuav tsum tsis txhob tos tham nrog peb.

Peb cov khoom tau txais kev lees paub dav dav thiab kev ntseeg siab los ntawm cov neeg siv khoom thiab tuaj yeem ua tau raws li cov kev xav tau ntawm kev lag luam thiab kev sib raug zooHauv qab Roller, TRACK ROLLER, Undercarriage qhov chaw, Nrog rau kev cob qhia qib siab, pab pawg tsim qauv thiab kev tswj hwm nruj, raws li qhov nruab nrab mus rau high-end cim raws li peb qhov kev lag luam, peb cov khoom muag muag sai sai rau European thiab Asmeskas kev lag luam nrog peb tus kheej hom xws li hauv qab no Deniya, Qingsiya thiab Yisilanya.

Lus Taw Qhia:

Ductile hlau, tseem hu ua ductile cam khwb cia hlau, nodular cam khwb cia hlau, kheej kheej graphite hlau, kheej kheej graphite cam khwb cia hlau thiab SG hlau, yog ib hom graphite-nplua nuj cam khwb cia hlau nrhiav tau nyob rau hauv 1943 los ntawm Keith Millis.Txawm hais tias feem ntau ntawm cov cam khwb cia hlau tsis muaj zog hauv qhov nro thiab nkig, cov hlau nplaum muaj ntau qhov cuam tshuam thiab qaug zog, vim nws cov nodular graphite suav nrog.Ductile hlau tsis yog ib qho khoom siv tab sis yog ib feem ntawm ib pawg ntawm cov ntaub ntawv uas tuaj yeem tsim nrog ntau yam khoom los ntawm kev tswj hwm lawv cov microstructure.Lub ntsiab txhais yam ntxwv ntawm pab pawg neeg ntawm cov ntaub ntawv no yog cov duab ntawm graphite.Hauv cov hlau nplaum, graphite yog nyob rau hauv daim ntawv ntawm nodules es tsis yog flakes li grey hlau.Whereas ntse graphite flakes tsim kev ntxhov siab cov ntsiab lus nyob rau hauv cov hlau matrix, rounded nodules inhibit tsim cov kab nrib pleb, yog li muab cov kev txhim kho ductility uas muab lub alloy nws lub npe.

Austempered ductile hlau (ADI; piv txwv li, austenite tempered [7]) tau pom nyob rau xyoo 1950, tab sis tau ua lag luam thiab ua tiav qee xyoo tom qab.Hauv ADI, cov qauv hlau yog siv los ntawm cov txheej txheem kho cua sov.

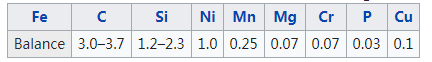

Kev sib xyaw

Pawg feem (%) rau ferritic ductile hlau castings[8]

Lwm cov ductile hlau compositions feem ntau muaj me me ntawm leej faj thiab.

Cov pa roj carbon monoxide 3.2-3.60%

Silicon, 2.2-2.8%

Manganese yog 0.1-0.2%

Magnesium yog 0.03-0.04%

Phosphorus 0.005-0.04%

0.005-0.02% tooj liab

tooj liab, <0.40%

Hlau, sib npaug

Cov ntsiab lus xws li tooj liab lossis tin tuaj yeem raug ntxiv kom muaj zog tensile thiab yield zog thaum ib txhij txo cov ductility.Kev txhim kho corrosion kuj tuaj yeem ua tiav los ntawm kev hloov 15-30% ntawm cov hlau hauv cov hlau sib txawv ntawm cov nickel, tooj liab, lossis chromium.

Silicon raws li graphite tsim lub caij tuaj yeem hloov pauv los ntawm txhuas los muab kev tiv thaiv oxidation zoo dua.[9]

HONGDA Ductile Hlau Castings:

Thaum ntxov xyoo 2021, HONGDA tau tsim lub Hoobkas tshiab los qhia cov khoom siv thiab cov kab ntau lawm rau Cov Hlau Hlau Casting.

1. Khoom siv: QT450#-10 thiab Spheroidization tus nqi yog dhau qib III kom tau txais qhov zoo ntawm castings los txhawb koj qhov kev thov.

2. Automated ntau lawm kab kom ncav cuag ib tug high efficiency thiab loj muaj peev xwm ntau lawm, 550T / hli, rov qab koj xav tau ceev.

3.Application: ductile hlau castings rau cov menyuam dab tshos, idler bracket thiab thiaj li zoo li qhov chaw castings nyob rau hauv 70KGS.Track cov menyuam nrog precision engineered Cheebtsam, ceev faj thaum tshav kub kub-kho thiab lub neej sealing system, cov chais yog assurded ntawm lub neej ntev.Cov menyuam plhaub yog forged. los ntawm sib sib zog nqus hardening hlau thiab yog tsim los tiv thaiv bellmouthing.Tag nrho cov rollers muaj warranty manufacturers.