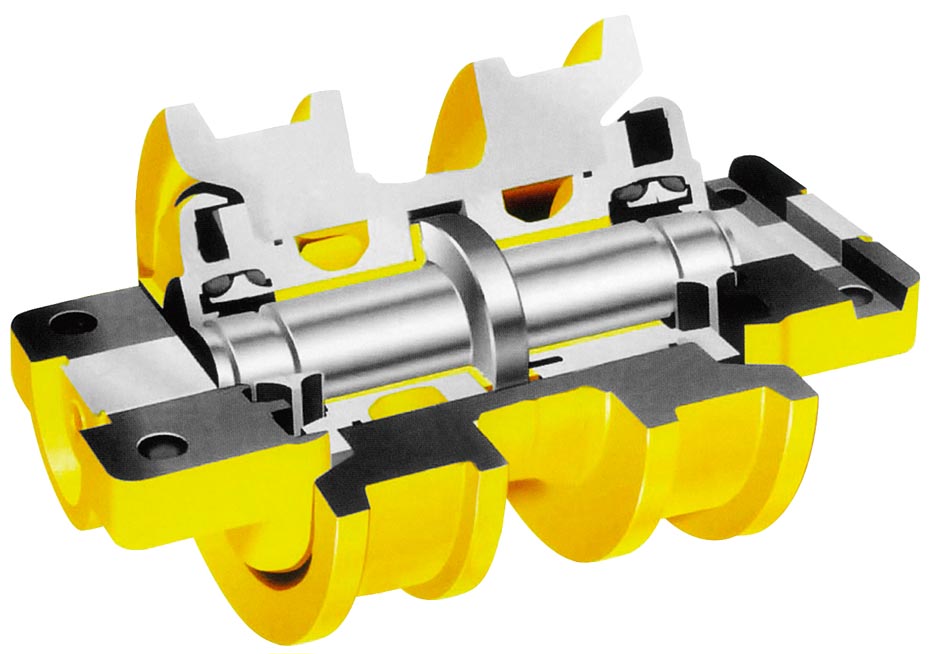

Cov qauv ntawm cov menyuam hauv qab feem ntau yog muab faib ua lub log lub cev, lub log txhawb nqa, lub tes tsho ncej, cov roj ntab ntim, thiab lub hau kawg.

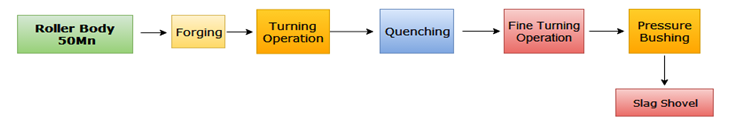

Ua kom zoo khiav cov menyuam feem ntau yog nyob ntawm kev ua haujlwm ntawm nws cov hlau.Cov khoom ntawm cov menyuam lub cev feem ntau yog 50Mn, 40Mn2, (MN: synonymous nrog manganese keeb).Cov txheej txheem raug muab faib ua casting lossis forging, machining, thiab tom qab ntawd kho cua sov.Tom qab lub npoo ntawm lub log yog quenched Lub hardness mus txog HRC55 ~ 58 kom nce qhov hnav tsis kam ntawm lub log nto.

Lub machining raug qhov yuav tsum tau ntawm cov kev txhawb nqa rollers yog qhov siab.Feem ntau, CNC tshuab cuab yeej yuav tsum tau rau machining kom tau raws li qhov yuav tsum tau muaj.

Muaj ntau cov ntaub ntawv ntawm 40Mn2, thiab hardness ncav cuag HRC52.

Dab tsi yuav tsum tau them sai sai rau thaum lub sijhawm ua haujlwm ntawm paver roller?

1. Thaum lub sijhawm ua haujlwm ntawm paver, qhov kev ncua deb mus rau ib lub sijhawm yuav tsum tsis txhob ntev dhau, thiab qhov ceev yuav tsum tsis txhob ceev heev;lub log kev txhawb nqa yuav tsim kom muaj qhov kub thiab txias thaum lub sij hawm mus sij hawm ntev tsav tsheb, thiab cov roj lubricating yuav tawm vim yog dilution.Ua rau kev puas tsuaj rau lub log txhawb nqa.Thaum pom tias cov menyuam raug puas lawm, nws yuav tsum tau hloov lub sijhawm, txwv tsis pub cov menyuam yaus uas nyob ib sab tseem yuav nrawm dua vim muaj zog ntau dhau.Thaum hloov cov kev txhawb nqa rollers, kev hnav khaub ncaws yuav tsum tau xav txog.Yog hais tias lub degree ntawm hnav yog me me, nws tuaj yeem hloov tau ib leeg, txwv tsis pub txhua yam yuav tsum tau hloov, thiaj li tsis ua kom nrawm hnav ntawm cov menyuam hloov tshiab.

2. Vim hais tias cov screed ntawm lub paver hnyav dhau lawm, qhov nruab nrab ntawm lub ntiajteb txawj nqus ntawm tag nrho lub tshuab yog deviated, yog li lub rear rollers ntawm paver dais lub zog loj tshaj plaws thaum lub sij hawm ua hauj lwm, uas yog ib qho yooj yim rau kev puas tsuaj, thiab paver yuav ua tau. puas yog puas lawm.Thaum taug kev, screed yuav nce thiab nqis, uas yuav ua rau txoj kev paving ua wavy, uas cuam tshuam ncaj qha rau txoj kev smoothness.

Cov teeb meem ua rau paver rollers:

1. Cov menyuam lub cev hnav.Yog vim li cas rau qhov xwm txheej no yog tias cov hlau siv tsis tsim nyog lossis cov khoom tawv tawv thaum kho cua sov tsawg, thiab hnav tsis kam.

2. Roj to.Lub bearing log ncej tas li tig los ntawm lub tes tsho ncej, thiab lub log lub cev yuav tsum tau lubricated kom nws du, tab sis yog hais tias lub nplhaib sealing tsis zoo, nws yog ib qho yooj yim ua rau cov roj to, kom cov ncej thiab lub tes tsho. yooj yim hnav thaum lawv tsis du.Cov khoom tsim yuav tsum tsis txhob siv.

Muaj ob peb lub laj thawj rau cov roj nchuav?

1. Tsis tsim nyog floating roj foob

2. Lub roundness ntawm lub tes tsho khoom tsis txaus

3. Tsis txaus gloss ntawm fulcrum

4. Cov roj iav tsis yog raws li tus qauv

5. Qhov teeb meem ntawm machining dimensional tolerances, thiab lwm yam yuav ua rau cov roj to hauv cov chais

JINJIA MACHINERY yog ib lub lag luam ua lag luam loj hauv engineering machinery nrog ntau yam ntawm cov khoom siv hauv qab ntawm cov menyuam hauv qab, cov menyuam yaus, sprocket, idler thiab khiav chains thiab taug qab khau thiab lub koob npe nrov txij li xyoo 1990.

Post lub sij hawm: Oct-23-2021